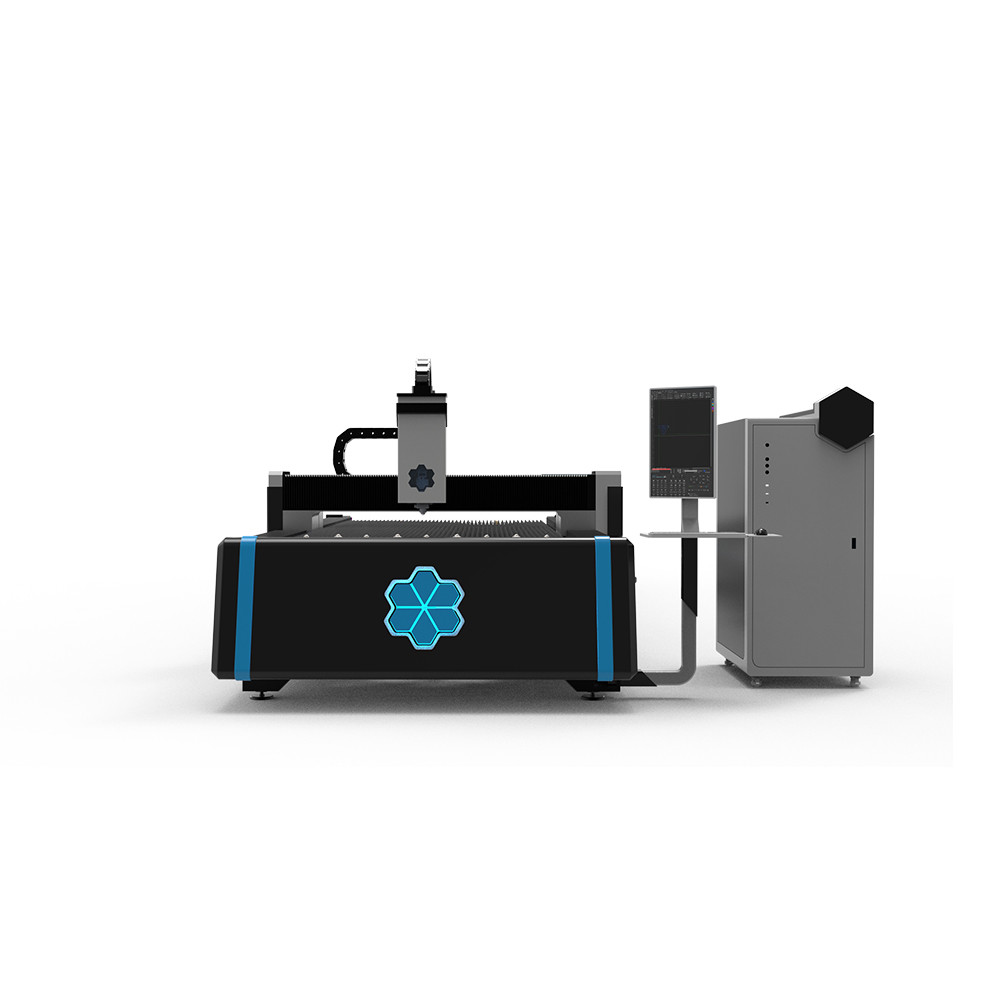

2021 Good Quality Cnc Laser Tube Cutter - Combine Exchange Platform With Tube Laser Cutting Machine – Glorious

2021 Good Quality Cnc Laser Tube Cutter - Combine Exchange Platform With Tube Laser Cutting Machine – Glorious Detail:

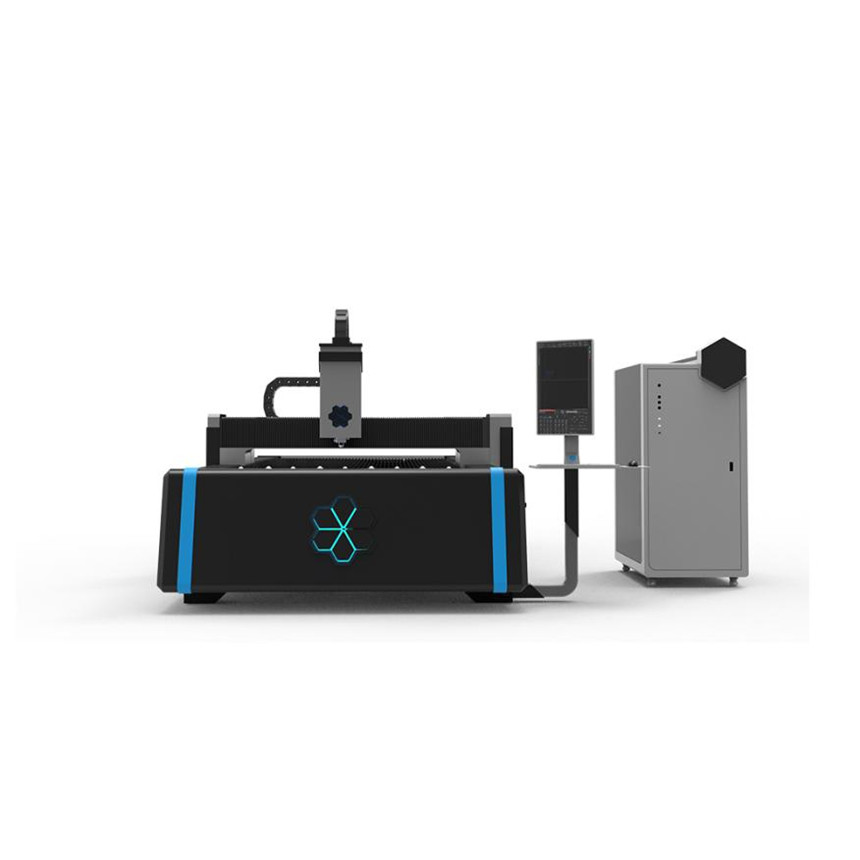

The product adopts the gantry double-drive structure, the bed is an integral weldment, a fully enclosed structure, with double exchange working platforms, Z-axis is light in weight, and has good dynamic performance. Both are rough processed after annealing and subjected to secondary vibration aging treatment. Afterwards, the overall finishing process is carried out to obtain extremely high form and position tolerance accuracy

The main frame of the fixed workbench: adopts the super-thick plate integral bending process, and then integrally welds it to form; thus, it has a great load-bearing capacity.

Parameter

| Item | Subitem | E3015T | E4020T | E6020T |

| Basic parameier | Working area | 3000mm*1500mm | 4000mm*2000mm | 6100mm*2000mm |

| Table load bearing | 900kg | 1600kg | 2400kg | |

| Machine overall dimensions | 9350*3300*2000mm | 10200*4100*2000mm | 15100*4100*2000mm | |

| Machine weight | E-T3: 8300kg E-T6: 8900kg |

E-T3: 13400kg E-T6: 14000KG |

E-T3: 18400 kg E-T6: 19000 kg |

|

| Z axis travel | 315mm | 315mm | 315mm | |

| Fastest exchange time of platforms | 13S | 17S | 30S | |

| Operalion parameter | Max. linkage speed | 100m/min | 100m/min | 100m/min |

| Max. acceleraTion | 1G | 1G | 1G | |

| Positioning accuracy | 0.05mm | 0.05mm | 0.05mm | |

| Repositioning accuracy | 0.03mm | 0.03mm | 0.03mm |

R&D and Design

1. What is the research and development idea of your company’s products?

Independent research and development.

2. What is the design principle of your product?

Stability, economy and innovation.

3. How often does your company’s products update?

6-12 months according to market demand.

4. What are the technical indicators of your products? If so, what are the specific ones?

Positioning accuracy Repeated positioning accuracy Running speed.

5. Can your company identify your own products?

Can

6. What are your plans for launching new products?

Patent layout in advance, return to the client’s functional requirements for new products, and participate in the exhibition.

7. What are the differences in your products among peers?

Product stability

8. What is the principle of the appearance of the company’s product design? What are the advantages?

Appearance design accords with ergonomics.

9. How are your products made up? What are the specific materials?

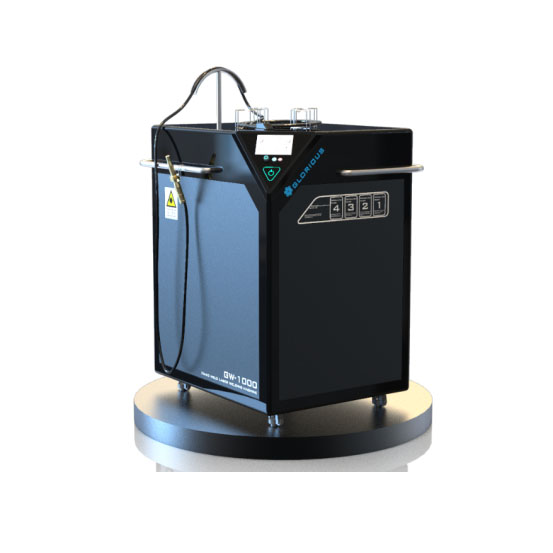

Bed Laser System Laser Head Chiller.

Product detail pictures:

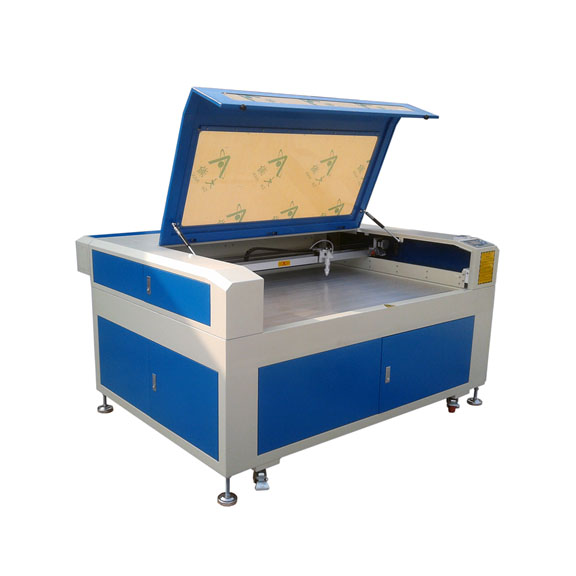

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our administration ideal for 2021 Good Quality Cnc Laser Tube Cutter - Combine Exchange Platform With Tube Laser Cutting Machine – Glorious , The product will supply to all over the world, such as: Sydney, Poland, French, We've got sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!